Product List

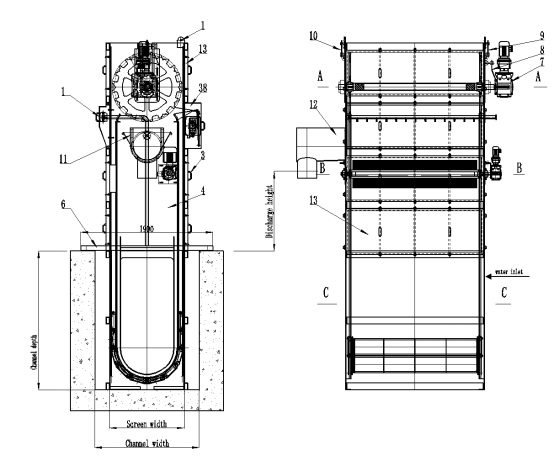

Travelling band screen is designed for fine filtration of surface and process water. It is fitted vertically in the inlet channel and therefore occupies only a small floor area.

Specifications:

Dimension: Customized

Material: SS304, SS316 or Customized

Channel depth: up to 16m

Channel width: up to 4m

Mesh opening: 2-6mm

Inclined angle: 90°

Motor brand: First-class motor, Nord or SEW is optional

-

Description

Travelling band screen is designed for fine filtration of surface and process water. It is fitted vertically in the inlet channel and therefore occupies only a small floor area.

Band screens are applied where a short water intake is necessary and where significant variations in surface water levels can occur.

The principle of operation is based on a conveyor belt. However, the belt is replaced by screen panels, which are mounted between two endless transport chains. The chains are driven by two sprockets.

The debris, which is trapped on the screen panels, is removed by high pressure spray water and discharged through a chute. The cleaning process can be executed automatically and semi-automatically.

The drive unit and spray water pipe are mounted above deck level under a steel or reinforced plastic housing.

Special models can be provided with facilities for removing and discharging other debris, such as jellyfish, seaweed etc.

-

Applications

Travelling Band Screens are used in cooling water intake systems, industrial cooling water intakes, irrigation, pretreatment of industrial or urban waste water, cooling tower outlets or for the pretreatment of drinking water.

-

Technical parameters

· Capacity: 2500-60000m³/hr.

· Mesh opening: 2-6mm.

· Channel depth: up to 16 m.

· Channel width: up to 4 m.

· Material: Steel coated or stainless steel Specific dimensions or materials on request.

-

Advantages

· Designed for easy maintenance (easy chain tension adjustment, simple replacement of bushes, screening mesh and spray nozzles)

· Come installed with anti-fiber screens, making them useful in water that has a high fibrous content.

· High quality construction and design ensures that no oil or grease will spill into the water

· All layouts of the band screen are available with full carrying structure or with rails and guides fixed to the civil works

· Dual-flow band screens can use an outside-to-inside flow and are the best solution for eliminating debris carryover

-

Related Products